About us

Frequently Asked Questions

Products Recommended

BREAD:HOME » Solution » Ribbon industry program Ribbon industry program

Ribbon materials - polyester fiber profile polyester fiber (polyester fibre) composed of organic dibasic acid and glycol polycondensation of polyester by the spinning of synthetic fibres. The polyethylene terephthalate is used in the industrial production of polyester fiber, which is called dacron. Is the current synthetic fiber of the first variety.

Dacron is a staple of synthetic fiber and is the name of the polyester fiber in China. It is pure terephthalic acid (PTA) and dimethyl terephthalate (DMT) and ethylene glycol (EG) as raw material through esterification and ester exchange and polycondensation reaction of fiber forming polymer, polyethylene terephthalate (PET), the spinning and aftertreatment fibers. Ribbon supplier.

In accordance with national standards, the standard publication has been issued in accordance with national standards. Since January 01, 2010, GB/T 4146.1-2009 "textile chemical fibre first part: generic name" has been officially implemented. Standard after implementation, inspection agencies inspection report issued by most began to "polyester fiber" instead of the usual "polyester", caused the attention of the enterprise and confused, and even some enterprises believed to be the new standard is cancelled "polyester" name of the fiber, is now on the issue that is as follows: for a long time, the definition of "polyester fiber" itself, it is not only refers to a kind of "polyester", it includes all the molecular chain contains more than 85% of benzene dicarboxylic acid glycol ester of linear macromolecular fibers, only in FZ/T 01053-2007 "textile fiber content of the logo" appeared "polyester fiber (polyester)", to "polyester fiber" and "polyester" equivalent. In fact, "polyester" is just a kind of "polyester fiber", in the GB/T 4146.1 2009 "textile chemical fiber, part 1: generic name", "polyester fiber" includes "polyethylene terephthalate oxalic ester (polyester PET)", "poly propylene terephthalate (PTT)" and "polyethylene terephthalate succinic ester (PBT)" three kinds of fibers. In actual testing, it is difficult to distinguish the three fibers through common methods. Therefore, according to the standard of GB/T 4146.1 2009 "textile chemical fiber, part 1: generic name", in general will issue a report "polyester fiber", only in the client specific requirements, and the samples can be determined is "poly (ethyl 2 terephthalate" cases, testing institutions can only be out for "polyester".

Performance:

1. High strength. Short fiber strength is 2.6 ~ 5.7 cN/dtex, high strength fiber is 5.6 polyester. ~ 8.0 cN/dtex. Due to its low hygroscopicity, its wet strength is basically the same as that of dry state. The impact strength is four times higher than nylon and 20 times higher than viscose fiber.

2. Good elasticity. The elastic approach to wool is almost completely restored when it is 5 to 6 percent elongated. Wrinkling resistance is more than other fiber, that is, the fabric is not creased, the dimensional stability is good. Elastic modulus is 22 ~ 141cN/dtex, 2 ~ 3 times higher than nylon.

3. Heat resistance and thermal stability are the best in synthetic fabrics.

4. The polyester surface is smooth and the internal molecules are closely aligned.

5. Good wear resistance. Wear resistance second only to the best nylon, better than other natural fibers and synthetic fibers.

6. Good light resistance. Light resistance is second only to acrylic.

7. Corrosion resistance. Bleaching agent, oxidizer, hydrocarbon, ketone, petroleum products and inorganic acid. The alkali is not afraid of mold, but it can be decomposed.

8. The dyeing sex is poor, but the color fastness is good, not easy to fade.

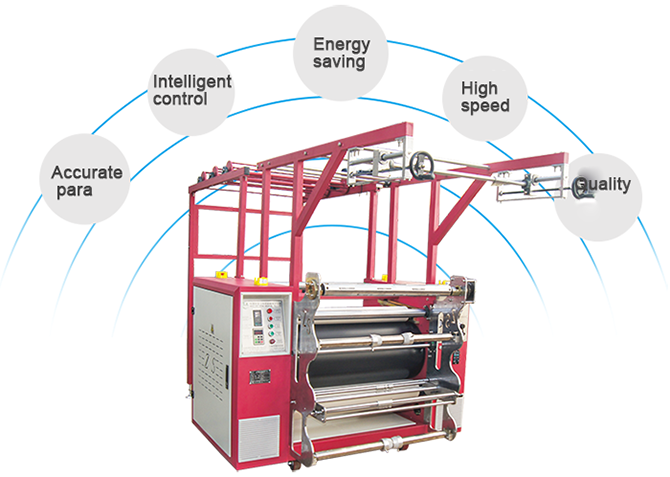

First machinery company to tailor the ribbon industry for a variety of high-end configuration of ribbon printing equipment models: ribbon double transfer printing machine ZS - AB, the products adopt far-infrared yuan precision, external, solved the difficult problem ribbon double-sided printing. The machine adopts two - to - two collection function, suitable for transfer: small cut, ribbon, elastic belt, shoelace, mobile phone hang rope, pet belt, zipper, etc. It is the first choice for the ribbon printing